Comprehensive implementation of the Traceability system, including the database and associated hardware.

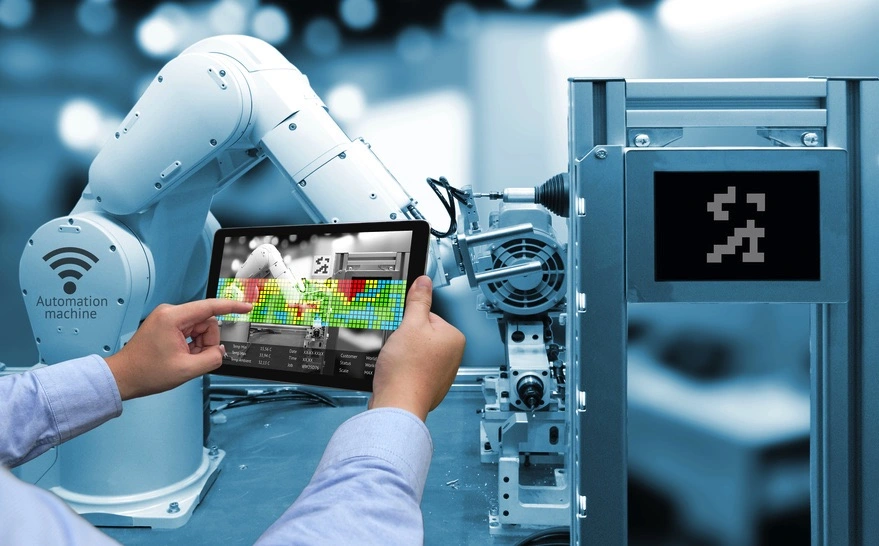

The goal of using automation in industry is to reduce human involvement in production processes in areas where work is associated with the repetitiveness of the production process. By selecting appropriate automation components, such as PLCs, industrial robots, conveyor elements, or entire assembly lines that work together, it enables cheaper and faster production of the highest quality goods in larger quantities

Our service includes:

The service is carried out by our best specialists. We have professionals with many years of experience in the industry. We are familiar with the specifics of many, even quite unusual devices and machines used in manufacturing companies. This allows us to provide a collaborative and effective partnership with the client and achieve the expected results.

Rundown time measurements

In accordance with the requirements set out in Directive 2009/104/EC of the European Parliament, the employer is obliged to carry out periodic inspections of the protective equipment of machines. After the measurements, the customer receives a detailed report including test results - the rundown time and the minimum safety distance - along with professional analysis and recommendations for the safety system.

Our offer includes ready-made solutions in the form of assembly stations that meet the current safety requirements, built on the basis of automation, pneumatics, and mechanics components from leading suppliers in these fields (Siemens, Festo, Metalwork, etc.).

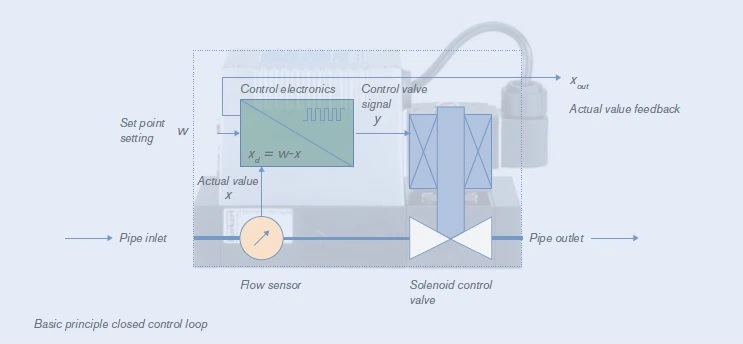

Leak testers.

Przemysłowy tester mierzący przepływ medium, który na podstawie ustawień technologicznych weryfikuję czy dany przepływ lub wyciek jest zgodny z założeniami procesowym.